Belt Conveyors

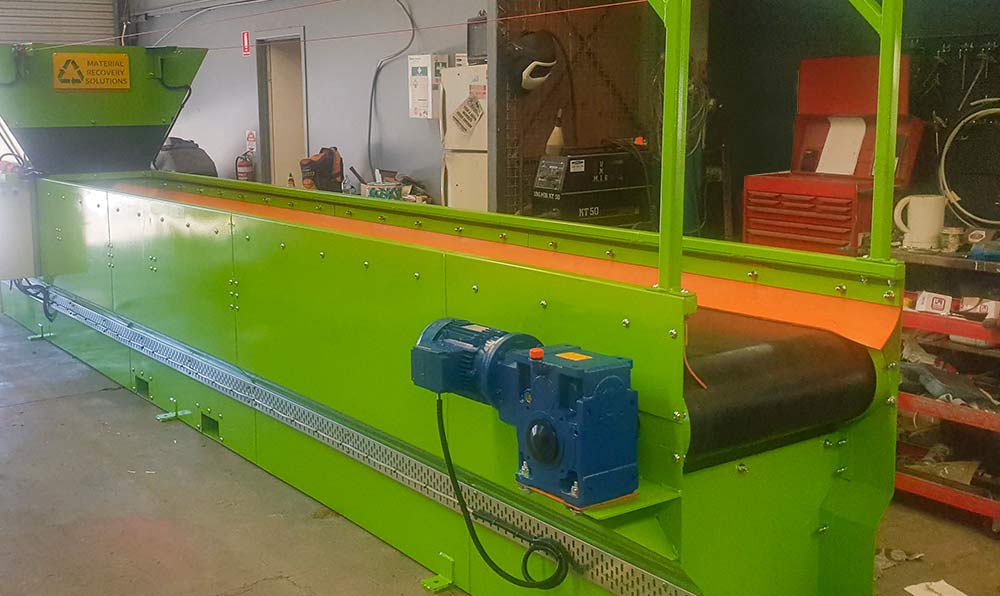

MRS Conveyor Belt

When it comes to productive material handling, MRS Conveyor Belt is at the forefront of the industry. These multifaceted conveyor belt systems are designed to carry a wide range of products, regardless of their shape or size, making them the perfect choice for businesses with diverse product lines. With a commitment to excellence and innovation, MRS Conveyor Belt sets the standard for reliability and performance in material handling solutions.

Conveyor belts play an integral role in a wide range of industries, from manufacturing operations to warehousing processes and large-volume distribution requirements. In manufacturing, these conveyor systems enhance productivity by naturally integrating into assembly line processes, assuring the smooth flow of materials and products. Warehousing operations benefit from the organised movement of parts and products, optimising storage and retrieval processes for increased efficiency.

Boosting Productivity Across Industries

These conveyor belts are also instrumental in sectors such as agriculture, postal services, and even critical infrastructure projects involving the distribution of materials like gravel and sand. Their versatility and reliability contribute to reduced labor costs, improved safety in material handling, and overall enhanced efficiency in various industries.

For businesses looking to streamline their operations and achieve new levels of efficiency, MRS Conveyor Belt is the trusted solution. Discover how these advanced conveyor systems can transform your material handling processes and elevate your business to new heights of success.

The Role of Conveyor Belt in Industry

Conveyor belts are super important in manufacturing, warehouses, and big distribution needs. They’re like the heartbeats of industry, keeping things moving smoothly from one stage to another. They’re a big part of how we work today, making things faster and more accurate in lots of different industries.

…In Manufacturing

In manufacturing, conveyor belt systems are like the brain of a factory or production place. They help materials move smoothly along the production line. This makes manufacturing better and keeps the quality of products consistent. Also, conveyor belts help reduce the need for people to move things around by hand and lower the chances of mistakes. This is really important for making work more efficient and keeping products safe.

…In Warehousing

Warehouses have changed a lot with conveyor belts. They help stores move things around easily, making storage, getting things out, and distributing them faster in big warehouses. With conveyor belts, stuff moves between storage places smoothly, which means less need for people to move things by hand and less chance of stuff getting damaged. This makes filling orders faster, managing inventory better, and overall, helps warehouses work better.

…In Large-Volume Distribution

Big distribution operations, like in stores, online shopping, or shipping, need conveyor belts a lot. They’re great at sorting, wrapping, and sending out lots of products fast, so they get to customers on time. Conveyor belts are super important for keeping up with the fast-moving business world and making sure things happen quickly and smoothly.

In short, the MRS Conveyor Belt is all about innovation and flexibility in handling materials. It goes above and beyond to meet the needs of businesses with different kinds of products. And conveyor belts in general are really important for making manufacturing, warehouses, and big distribution work better and faster across lots of different industries.

In addition to belt conveyors, Material Recovery Solutions also offers a range of chain conveyors designed for specific material handling needs.

Applications

MRS Belt Conveyors aren’t just for one industry—they’re used in lots of different ones. They help move things like farm produce in agriculture and sort and send mail in postal services. They’re really important in manufacturing too, where they fit right into how things are made, making work faster and more accurate.

Beyond Material Distribution

Additionally, they play a pivotal role in the efficient distribution of materials like gravel and sand, contributing to critical infrastructure projects. Moreover, within the domain of warehouse management, these conveyor systems facilitate the smooth and organised movement of parts and products, assuring the optimisation of storage and retrieval processes.

However, the advantages of belt conveyors don’t stop there. They offer improved efficiency, reduced labor costs, and increased safety in material handling. To delve deeper into the benefits and advantages of incorporating these versatile systems into your business operations, explore what IQS Directory has discovered about belt conveyors.

Other Information

Material Recovery Solutions stands out as a leading authority in conveyor belt system customisation, offering versatile solutions that cater to your unique business needs. Whether you require a fixed or mobile conveyor system, we can tailor it to your specifications. Our extensive range of conveyor belts covers all conceivable lengths, widths, and heights of conveyor systems. We provide both manual and automated systems, including straight-line, incline, or decline configurations, along with curved elements, enabling us to address the full spectrum of your material handling requirements.

Endless options for customisation

Furthermore, we offer various options for conveyor belt design, drive positions, belt speed, and emergency stopping stations, all thoughtfully designed to align with your business’s specific operational procedures and guidelines.

Get started today

This all-around approach to customisation makes sure that your conveyor belt system naturally integrates into your existing infrastructure, improving operational efficiency while minimising downtime. With MRS Belt Conveyors, you’re not just investing in a conveyor system; you’re investing in a “specific to your company” solution that empowers your business to reach new heights of productivity and precision, setting you apart as an industry leader in efficient material handling practices.

Contact Us

Our knowledgeable staff is here to help you find the right solution for your business's specific needs. Call us now or use this form to contact us.

07 562 900 92

sales@materialrecoverysolutions.com.au

26 Blue Rock Drive

Luscombe, QLD 4207